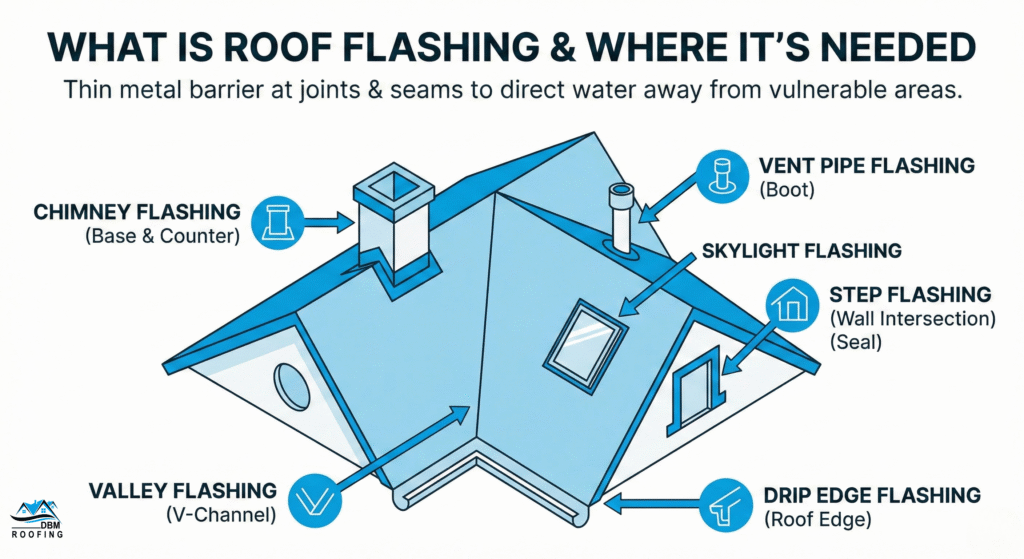

The short answer: Roof flashing is thin metal material installed at joints, seams, and transition points on your roof to direct water away from vulnerable areas. Without it, your home would be defensively unprotected at the exact spots where roof leaks most commonly occur.

Think of flashing as your roof’s first line of defense at every point where different surfaces meet. Where your chimney rises through the roofline, where a skylight sits, where vent pipes poke through the shingles, and where roof planes intersect at valleys, you need a barrier that water cannot penetrate. That barrier is flashing.

For homeowners in Georgia and the South Carolina Low Country, understanding roof flashing matters even more than it might elsewhere. Heavy rainfall, humidity, and severe weather conditions put extra stress on every roofing component. When flashing fails, the consequences show up quickly in the form of water intrusion, mold, and structural damage that can cost thousands to repair.

How Roof Flashing Works

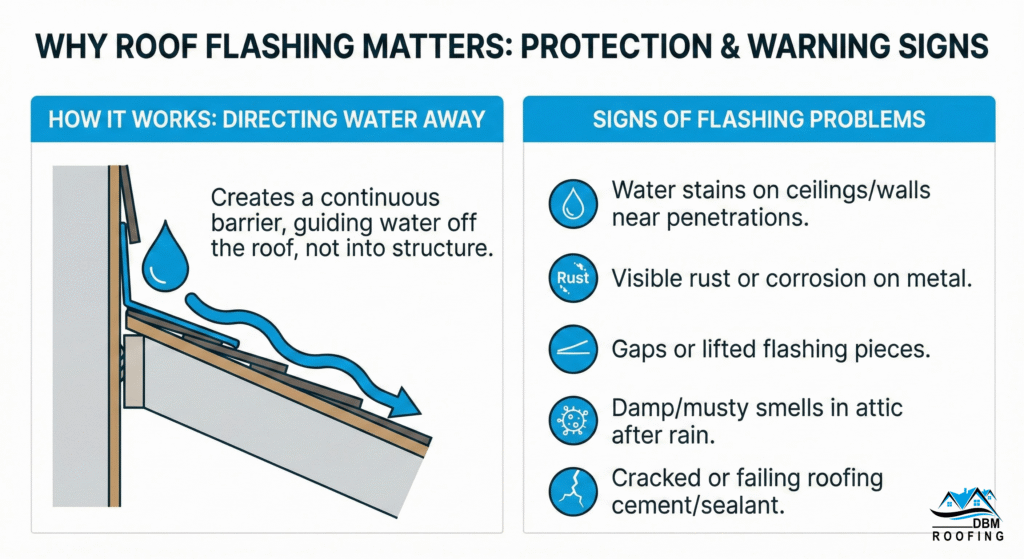

Flashing creates a watertight seal at critical areas where roofing material alone cannot fully protect your home. The metal extends beneath roof shingles on one side and up against vertical surfaces on the other, channeling water down and away rather than allowing it to seep into joints and gaps.

The principle is simple: water follows the path of least resistance. Proper flashing installation ensures that path leads safely off your roof rather than into your attic or walls. When a professional roofer installs flashing correctly, each piece overlaps to create a continuous barrier against moisture.

Different Types of Roof Flashing

Not all flashing serves the same purpose. Each type addresses specific vulnerable areas on your roof.

Step Flashing protects where a roof plane meets a vertical surface like a wall or dormer. These L-shaped pieces are installed in a stair-step pattern, with each piece overlapping the one below it to guide water downward.

Chimney Flashing typically involves multiple components working together. Base flashing wraps around the bottom of the chimney where it meets the roof, while counter flashing is embedded into the chimney mortar and folds down over the base flashing to create a watertight seal. Apron flashing covers the front edge where the chimney meets the roof slope.

Valley Flashing protects roof valleys, the V-shaped channels where two roof planes meet. These areas see concentrated water flow during heavy rainfall, making them particularly vulnerable to leaks if flashing is compromised or missing.

Vent Pipe Flashing (also called pipe flashing or pipe boot) seals around plumbing vent stacks that penetrate your roof. This cone-shaped component has a rubber or neoprene boot that fits snugly around the vent pipe.

Drip Edge Flashing runs along the edges of your roof, directing water away from the fascia and into your gutters rather than allowing it to run down behind them.

Skylight Flashing creates a weather-tight seal around skylights, which represent large openings in your roofing system that require special attention.

Continuous Flashing (also called apron flashing in some applications) is a single long piece used where a roof meets a vertical wall in a straight line.

Flashing Materials: What Your Roof Needs

Different materials offer different advantages depending on your roof type and local weather conditions.

Aluminum Flashing is lightweight, easy to work with, and resists corrosion. It works well for most residential applications and can be painted to match your home. However, in coastal areas, salt air can cause faster deterioration than you might see inland.

Copper Flashing is the premium choice for longevity. It naturally develops a protective patina over time and can last as long as your roof itself. Copper flashing costs more upfront but often pays for itself by avoiding premature replacement.

Galvanized Steel Flashing offers strength and affordability. The zinc coating provides corrosion resistance, making it a solid choice for many homeowners. This material performs well on metal roof installations.

Stainless Steel Flashing combines strength with excellent corrosion resistance, making it particularly suitable for homes near the coast where salt air accelerates metal degradation.

Lead Flashing is extremely malleable and long-lasting, traditionally used around chimneys. It conforms easily to irregular surfaces but is less common today due to environmental concerns.

Your roofing contractor can recommend the best flashing material based on your roof type, local conditions, and budget.

Warning Signs of Flashing Problems

Flashing can fail before the rest of your roof shows any wear. Watch for these indicators that your flashing needs attention:

- Water stains on ceilings or walls near chimneys, skylights, or where your roof meets a wall often point directly to flashing issues. The location of the stain usually corresponds to a flashing component directly above.

- Visible rust, corrosion, or deterioration on exposed metal flashing indicates the material is breaking down and losing its protective capability.

- Gaps between flashing and the surfaces it should seal against allow water intrusion. Roofing cement used to seal these gaps can crack and fail over time.

- Missing or lifted flashing after severe weather requires immediate attention before the next rain causes interior damage.

- Damp or musty smells in your attic during or after rainfall suggest water is finding its way in somewhere, and compromised flashing is a common culprit.

Why Proper Installation Matters

Even high-quality flashing material cannot protect your home if it is installed incorrectly. Proper installation requires understanding how water behaves on a roof and ensuring every piece overlaps correctly to shed moisture rather than trap it.

Common installation errors include failing to extend flashing far enough under shingles, using incompatible materials that cause galvanic corrosion, leaving gaps in coverage at corners or transitions, and relying too heavily on roofing cement rather than proper mechanical attachment.

This is why working with an experienced roofing contractor matters so much. A roof inspection that includes checking flashing condition can catch problems early, before they cause interior water damage that requires costly repairs.

Coastal Climate Considerations

Homeowners in Savannah, Richmond Hill, Brunswick, and throughout the Georgia and South Carolina coast face unique challenges. The combination of salt air, high humidity, and frequent heavy rainfall accelerates wear on roofing components, including flashing.

Salt deposits can corrode metal flashing faster than you might expect. Harsh weather conditions during hurricane season test every seam and seal on your roof. The intense summer sun bakes roofing cement and rubber components, causing them to crack and fail prematurely.

For these reasons, regular roof maintenance and inspections take on extra importance in coastal areas. What might last decades inland may need attention much sooner when exposed to coastal conditions.

When to Call a Professional

While minor flashing repairs might seem like a weekend project, proper repair often requires understanding how your specific roof system functions. What looks like a simple fix can actually compromise water protection if done incorrectly.

Call a professional roofer when you notice any signs of water intrusion, when flashing is visibly damaged or deteriorated, after severe weather has affected your area, or if your roof is approaching its expected lifespan and you want to assess overall condition.

During any roof replacement project, all flashing should be evaluated and typically replaced to ensure the new roof can perform as expected for its full lifespan.

Protecting Your Investment

Your roof represents a significant investment in your home’s protection and value. Flashing is a relatively small component of that system, but its failure can lead to disproportionately large consequences, from water damage to structural integrity issues.

DBM Roofing brings more than ten years of experience helping homeowners throughout Georgia and the South Carolina Low Country protect their homes from the elements. We understand the specific challenges that coastal and southeastern weather conditions present, and we know how to address them with quality materials and expert installation.

Whether you need a complete roof repair or simply want an assessment of your current flashing condition, our team can provide the guidance you need. Contact DBM Roofing for an inspection and get straight answers about what your roof needs to keep your home protected for years to come.